The most valued

Tungsten Disulfide Properties

Properties of Tungsten Disulfide (Dicronite®)

Once engineers learn that Dicronite® dry film lubrication may very well solve their lubrication challenges, the conversation often turns to the solid lubricant’s properties.

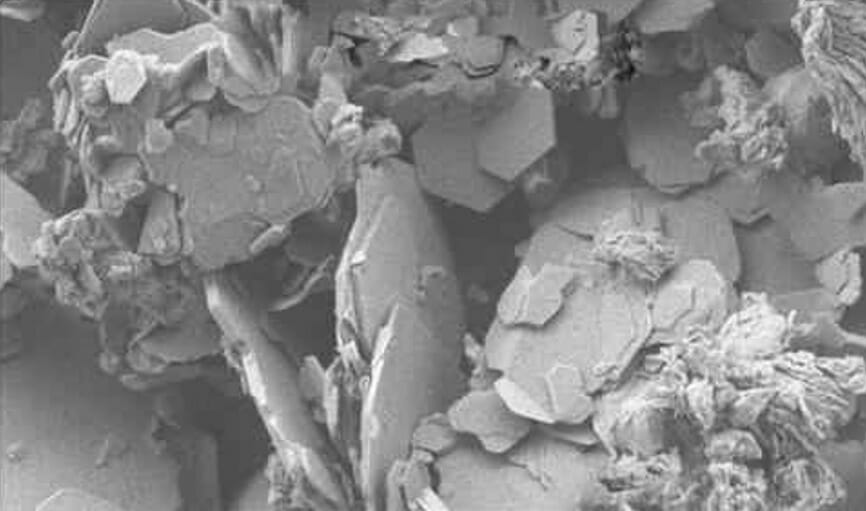

Dicronite® DL-5® is a modified tungsten disulfide powder (also spelled “tungsten disulphide”). Tungsten disulfide can be mined naturally as tungstenite, or it can be synthetically produced by combining Tungsten and Sulfur (WS2).

The inorganic WS2 compound has a lamellar, or crystalline structure similar to that of MoS2. The Dicronite® process modifies the WS2 compound without changing molecular structure and produces an extremely lubricious powder that, when impingement applied to customer parts, creates an exceptionally thin, remarkably slick film that molecularly adheres to the substrate surface.

Dicronite® Coating

Thickness

One of the most valued Dicronite® properties is the coating’s thickness. Because the particles will not bond to themselves and are of a controlled size, the solid lubricant film is not more than 0.5 microns thick.

This makes it very attractive to designers challenged with adding the lubricant to already designed parts and components. Avoid redesign by ensuring tolerances remain unaffected.

This ultra thin coating is a silver-gray, polished rhodium color, but the finished coating color can differ depending on the color and finish of the substrate underneath.

Industries Served

Wide Temperature Range

The coating is stable in extreme temperatures:

-350° F to +1000° F or (-188° C to +538° C) in air.

-350° F to +2400F (-188° C to +1316° C) in vacuum.

Tungsten disulfide’s ability to withstand a wide temperature range is a key reason for Dicronite®’s development for use on NASA’s Apollo missions.

The coating continues to be used in unique and harsh environments today.

Additional Properties for Consideration

- Dicronite® does not affect surface electrical properties.

- Dicronite® is inert, non-magnetic and completely safe for the environment

- Dicronite® withstands loads to 350,000 psi (approximately 2,450 MPa)

- Dicronite® is compatible with oils, greases, hydraulic fluids, and fuels

- Dicronite® is biocompatible. It has been tested in accordance with ISO-10993 and United States Pharmacopoeia (USP) Class 6. Application specific approvals have been received from both the United States Food and Drug Administration (US-FDA) and the United States Department of Agriculture (USDA).

Specialized Application Process

The Dicronite® coating can be applied on many substrates, including all metals and most plastics, and is often applied on top of other coatings such as TiN, CrN, CrC or Nickel.

With a hardness rating of 1.0-1.5 on the Moh’s scale, it is relatively soft. This, along with the material’s low shear stress between molecular layers, enables Dicronite® to provide exceptional lubricity.

It can be applied in soft–soft, soft–hard, hard–hard, or many other variations of substrate surfaces. The coating can be applied to holes, inside diameters and/or inside surfaces. It is possible to mask off or protect portions of the substrate or part so that they do not receive Dicronite® dry lubrication.

In order to bond Dicronite® to customer parts, the powder is sprayed at very high velocity onto the substrate at one of 11 Dicronite® licensed facilities.

This impingement process requires no binders, adhesives, solvents or cure time, and occurs at ambient temperatures.

The coating can be applied to holes, inside diameters and/or inside surfaces. It is possible to mask off or protect portions of the substrate or part so that they do not receive Dicronite® dry lubrication.

The original Tungsten Disulfide coating.

Dicronite® is a dry film lubrication made up of tungsten disulfide.

It can be applied to all metals, most plastics and some ceramics; may be applied on other coatings and platings as well.

COATING THICKNESS – 0.5 micron (0.00002 inch) or less

THERMAL STABILITY – up to 538°C in air; 1316°C in vacuum

COMPATIBILITY – compatible with greases, oils, fuels, fluids, and many solvents.

Dicronite® is applied at one of many worldwide licensed coating facilities.

After surface preparation, Dicronite® is impinged onto the surface at high velocity.

The material includes no binders or adhesives and requires no curing.

All you have to do is:

- Tell us about your application

- Send components to one of our application facilities

- Receive your expertly coated parts with little lead time.

Dicronite® has various application facilities that can provide the following quality certifications:

NADCAP

ITAR

ISO9001

AS9100

Submit an official quote today.

Additional questions regarding the properties of tungsten disulfide?

Our experts are here to help.

con este recubrimiento no es necesario aplicar ningún lubricante? cada cuando se debe aplicar?