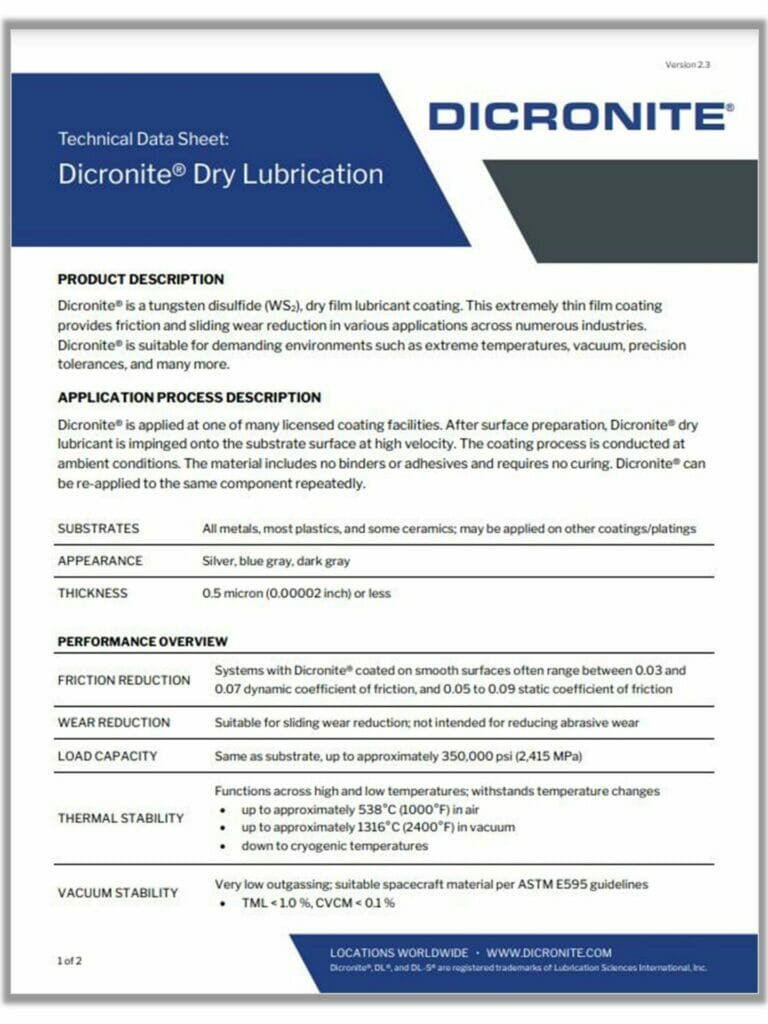

Technical Information:

Dicronite® Dry Lubrication

Quick & Helpful Documents:

PRODUCT DESCRIPTION

Dicronite® is a tungsten disulfide (WS2), solid lubricant coating. This extremely thin film coating provides friction and sliding wear reduction that improves performance in various applications across numerous industries

APPLICATION PROCESS DESCRIPTION

Dicronite® is applied at one of many licensed coating facilities. After surface preparation, Dicronite® dry lubricants impinged onto the substrate surface. The coating process is conducted at ambient conditions. The material includes no binders or adhesives and requires no curing. Dicronite® can be re-applied without extensive stripping.

COATING INFO

ACCEPTABLE SUBSTRATES

All metals, most plastics, and some ceramics; may be applied on other coatings/platings

APPEARANCE

Silver, blue gray, dark gray

THICKNESS

0.5 micron (0.00002 inch) or less

PERFORMANCE OVERVIEW

FRICTION REDUCTION

Application systems with Dicronite® coated on smooth surfaces typically range between 0.03 and 0.07 μ𝑘 (dynamic coefficient of friction)

WEAR REDUCTION

Reduces sliding wear; not appropriate for abrasive wear reduction

LOAD CAPACITY

Same as substrate, up to approximately 350,000 psi (2,415 MPa)

THERMAL STABILITY

Stable across wide temperature range; withstands temperature swings

- up to approximately 538°C (1000°F) in air

- up to approximately 1316°C (2400°F) in vacuum

- down to approximately -188°C (-305°F)

VACUUM STABILITY

Very low outgassing; suitable spacecraft material

TML < 1.0 %, CVCM < 0.1 %

COMMON APPLICATIONS

Actuators

Ball Screws

Bearings

Bushings

Chains

Couplings

Fasteners

Gears

Guides

Molds

Pins

Shafts

Sprockets

Valves

ADDITIONAL COATING INFO

CHEMICAL STABILITY

Inert

TOXICITY

Non-toxic

HARDNESS

1.0 – 1.5 on Mohs’ scale

MAGNETISM

Non-magnetic

HANDLING

Sensitive to scratching and abrasion; prevent damage to coated surfaces

APPLICATION CONSIDERATIONS

SUBSTRATE DEFORMATION

Will not induce stress to substrate

CORROSION RESISTANCE

Provides only minimal corrosion inhibition

CONDUCTIVITY

Will not significantly affect surface conductivity (thermal or electrical)

CO-LUBRICATION

Compatible with oils and greases

LIQUIDS COMPATIBILITY

Sensitive to scratching and abrasion; prevent damage to coated surfaces

OXYGEN COMPATIBILITY

Suitable for liquid and gaseous oxygen systems

RADIATION STABILITY

Stable (tested according to LEO and nuclear containment vessel radiation levels)

BIOCOMPATIBILITY

Biocompatible per USP Class VI and ISO-10993 testing

FACILITY LOCATIONS

Domestic

California – Minnesota

Georgia – Massachusetts

International

Mexico – The Netherlands – Germany

India – South Korea